If you’ve ever wondered how Toms shoes are made, you’re in for a treat! Get ready to dive into the fascinating world of shoe production, where creativity and craftsmanship come together to create the iconic Toms footwear. From the moment the materials are sourced to the final touches on each pair, the process is a labor of love that ensures quality and comfort. So, let’s lace up our shoes and embark on a journey to uncover the secrets behind the making of Toms shoes!

When it comes to crafting Toms shoes, the process begins with selecting the finest materials. From sustainable fabrics to durable soles, every component is carefully chosen to deliver both style and substance. Skilled artisans then take these materials and bring them to life, using their expertise to cut, sew, and assemble each pair with precision. Throughout the production process, quality control measures are in place to ensure that every shoe meets the high standards set by Toms. From the stitching to the finishing touches, no detail is overlooked. So, whether you’re slipping on a pair of classic canvas Toms or stepping into a stylish leather design, you can rest assured knowing that your shoes have been made with care and craftsmanship.

Now that we have a glimpse into the intricate process of making Toms shoes, we can truly appreciate the artistry and dedication that goes into each pair. So, the next time you slip on your favorite Toms, take a moment to marvel at the journey they’ve taken, from raw materials to

How Are Toms Shoes Made?

Toms shoes have become increasingly popular in recent years, known for their comfortable designs and commitment to social responsibility. But have you ever wondered how these shoes are made? In this article, we will take a closer look at the manufacturing process behind Toms shoes and explore the materials and techniques used to create these beloved footwear.

The Materials Used in Toms Shoes

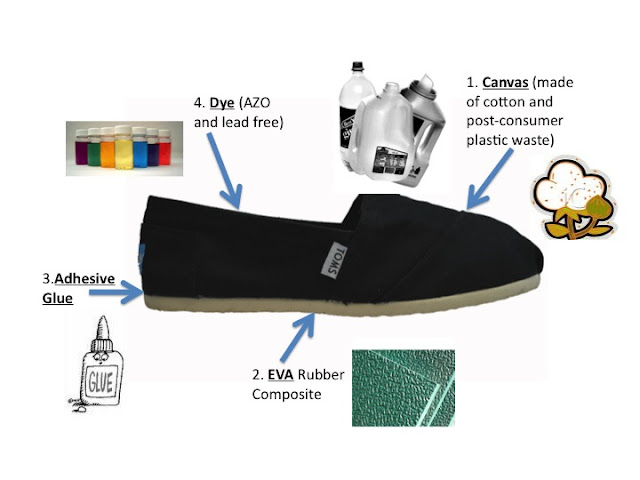

Toms shoes are crafted using a variety of materials that prioritize both comfort and sustainability. One of the key components of Toms shoes is canvas, a durable and breathable fabric that is commonly used in casual footwear. Canvas allows for flexibility and helps to keep the shoes lightweight, making them ideal for everyday wear.

In addition to canvas, Toms also incorporates other materials such as leather and suede into their shoe designs. These materials add a touch of elegance and durability to certain styles, while still maintaining the overall comfort and versatility that Toms shoes are known for. By using a combination of these materials, Toms is able to offer a wide range of styles to suit different preferences and occasions.

The Manufacturing Process

The manufacturing process of Toms shoes begins with the cutting of the materials. Depending on the style, the canvas or leather is cut into specific shapes and sizes that will later be assembled into the final shoe. Precision and attention to detail are crucial during this stage to ensure that each component fits together seamlessly.

Once the materials have been cut, they are then stitched together by skilled artisans. Toms shoes are known for their hand-sewn construction, which adds a level of craftsmanship and quality to the final product. This traditional technique allows for greater flexibility and durability, ensuring that the shoes can withstand daily wear and tear.

After the stitching process, the shoes go through a series of finishing touches. This includes attaching the outsole, adding any necessary reinforcements, and applying any desired embellishments or branding details. Each step is carefully executed to ensure that the shoes meet the high standards set by Toms.

The Commitment to Social Responsibility

One of the key aspects that sets Toms shoes apart is their commitment to social responsibility. For every pair of Toms shoes purchased, the company donates a pair of shoes to a child in need. This initiative, known as the “One for One” program, aims to improve access to education and protect children from preventable diseases that can be caused by walking barefoot.

Toms also places a strong emphasis on ethical manufacturing practices. The company works closely with its suppliers to ensure fair wages and safe working conditions for all employees. Additionally, Toms strives to minimize its environmental impact by using sustainable materials and implementing eco-friendly manufacturing processes.

The Impact of Toms Shoes

Since its inception, Toms has made a significant impact on communities around the world. Through the “One for One” program, millions of children have received new shoes, giving them the opportunity to attend school and pursue their dreams. Toms has also partnered with various organizations to provide clean water, safe birth kits, and other essential resources to those in need.

In addition to its philanthropic efforts, Toms has inspired other companies to adopt similar business models that prioritize social and environmental responsibility. The success of Toms has shown that it is possible to create a profitable business while making a positive impact on the world.

In conclusion, Toms shoes are made with a combination of high-quality materials and skilled craftsmanship. The company’s commitment to social responsibility sets it apart from other footwear brands, making it a popular choice for those who want to make a difference with their purchase. Whether you’re looking for a comfortable pair of shoes or want to support a company with a meaningful mission, Toms is a brand worth considering.

Key Takeaways: How Are Toms Shoes Made?

- Toms shoes are made through a process called “cut and sew.”

- The materials used to make Toms shoes include canvas, rubber, and leather.

- Toms shoes are known for their comfortable and casual style.

- For every pair of Toms shoes purchased, the company donates a pair to a child in need.

- Toms shoes are manufactured in various countries around the world.

Frequently Asked Questions

Here are some frequently asked questions about the manufacturing process of Toms shoes:

Q: What materials are used to make Toms shoes?

A: Toms shoes are made using a variety of materials, including canvas, leather, and rubber. The uppers of the shoes are typically made from canvas, which is a durable and breathable fabric. The soles are made from rubber, which provides traction and cushioning. Some Toms shoes also feature leather accents or linings for added style and durability.

Additionally, Toms uses sustainable and eco-friendly materials in their shoe production. For example, they offer vegan-friendly options that are made without any animal products.

Q: How are Toms shoes assembled?

A: The assembly process of Toms shoes involves several steps. First, the uppers of the shoes are cut from the chosen materials, such as canvas or leather. These pieces are then stitched together to create the shoe’s shape. The soles are attached to the uppers using adhesive or stitching, depending on the shoe model.

Once the shoes are assembled, they go through quality control checks to ensure they meet Toms’ standards. This includes checking for any defects in the materials or construction and making any necessary adjustments or repairs.

Q: Where are Toms shoes made?

A: Toms shoes are manufactured in various countries around the world. They have production facilities in China, Ethiopia, and other locations. Toms works closely with their manufacturing partners to ensure fair labor practices and ethical production standards. They prioritize transparency and accountability throughout their supply chain.

In addition to their own manufacturing facilities, Toms also collaborates with external suppliers and artisans to create unique designs and support local communities.

Q: Are Toms shoes sustainable?

A: Toms is committed to sustainability and social responsibility. They strive to minimize their environmental impact through various initiatives. For example, Toms uses recycled materials in their shoe packaging and incorporates eco-friendly components in their shoe designs.

Furthermore, Toms operates a One for One program, where for every pair of shoes sold, they donate a pair to a person in need. This approach promotes the circular economy and helps to address global footwear disparities.

Q: Can I customize my own pair of Toms shoes?

A: Yes, Toms offers a customization service called Toms Passport. With Toms Passport, you can design your own unique pair of shoes by choosing different colors, patterns, and materials. This allows you to create a personalized look that reflects your individual style.

Customization options may vary depending on the shoe model and availability. Toms Passport provides a fun and creative way to express yourself through your footwear while supporting Toms’ mission of giving back.

The Rise And Fall Of Toms

Final Summary: Unlocking the Craftsmanship Behind Toms Shoes

After delving into the fascinating world of Toms Shoes, it’s clear that their production process is a labor of love, infused with passion, sustainability, and social impact. From sourcing eco-friendly materials to supporting local artisans, Toms goes beyond just creating stylish and comfortable shoes. They strive to make a positive difference in the world.

Throughout this article, we’ve explored the intricate steps involved in making Toms Shoes. Starting from the careful selection of sustainable materials, such as recycled plastic bottles and vegan-friendly fabrics, to the skillful craftsmanship of the dedicated artisans, every detail is meticulously considered. Toms’ commitment to ethical manufacturing practices and fair wages ensures that each pair of shoes is not only fashionable but also socially responsible.

In conclusion, Toms Shoes exemplifies the perfect blend of style, comfort, and purpose. By choosing Toms, you’re not just getting a pair of shoes; you’re becoming part of a movement that supports sustainability and helps provide shoes to those in need. So, why settle for ordinary footwear when you can stride confidently in a pair that makes a positive impact on the world? Step into a pair of Toms Shoes and join the journey towards a brighter future, one step at a time.