When it comes to footwear, Toms shoes have become a popular choice for many fashion-forward individuals. But have you ever wondered how these trendy shoes are made? In this article, we’ll take a closer look at the manufacturing process behind Toms shoes and uncover the secrets that make them so unique and stylish.

Toms shoes are not just your average pair of kicks. They are crafted with care and precision to ensure both comfort and style. The manufacturing process starts with selecting high-quality materials, such as canvas for the upper part of the shoe and rubber for the sole. These materials are then meticulously cut and shaped to create the desired design. From there, skilled artisans stitch the pieces together, paying attention to every detail to ensure durability and longevity. Each pair of Toms shoes goes through a series of quality checks to guarantee that they meet the brand’s high standards. So, whether you’re walking down the street or hitting the dance floor, you can be confident that your Toms shoes are built to last. So now, let’s dive deeper into the fascinating world of Toms shoe manufacturing and discover the magic behind these trendy footwear options.

How Are Toms Shoes Manufactured?

Toms shoes have become a popular choice for many individuals due to their stylish designs and commitment to social responsibility. But have you ever wondered how these shoes are manufactured? In this article, we will take a closer look at the manufacturing process of Toms shoes and explore the steps involved in bringing these fashionable and socially conscious footwear to life.

The Design Process

The journey of a Toms shoe begins with the design process. A team of talented designers works to create unique and innovative designs that capture the essence of the Toms brand. They draw inspiration from various sources, such as fashion trends, customer feedback, and the company’s mission of making a positive impact. Once the designs are finalized, they are translated into technical drawings and specifications that serve as the blueprint for production.

Next, the design team collaborates with materials experts to select the finest materials for each shoe model. Toms is committed to using sustainable and ethically sourced materials whenever possible. This dedication ensures that the shoes are not only fashionable but also environmentally friendly.

The Cutting and Stitching Process

Once the materials are sourced, the manufacturing process begins with cutting. Skilled workers use precise cutting machines to cut the fabric and other materials into the desired shapes and sizes. This step requires careful attention to detail to ensure accuracy and minimize waste.

After the cutting process, the various components of the shoe are stitched together. Highly skilled craftsmen and craftswomen use specialized sewing machines to stitch the upper part of the shoe to the sole. This delicate process requires precision and expertise to create a durable and comfortable shoe.

The Assembly and Finishing Process

After the stitching process, the shoes go through assembly and finishing. Skilled workers meticulously attach any additional components, such as eyelets, laces, and logos, to complete the shoe’s construction. This stage also involves quality control checks to ensure that each shoe meets Toms’ high standards.

Once the shoes are assembled, they undergo a series of finishing processes to enhance their appearance and durability. This may include cleaning, buffing, and polishing the shoes to achieve a smooth and flawless finish. The shoes are then inspected once again to ensure that they are up to Toms’ quality standards.

Ensuring Social Responsibility

One of the unique aspects of Toms’ manufacturing process is their commitment to social responsibility. For every pair of shoes sold, Toms donates a pair to a person in need. This philanthropic approach is known as the “One for One” movement and has made Toms a leader in corporate social responsibility.

Toms works with carefully selected giving partners to distribute the donated shoes to communities in need around the world. This ensures that the shoes reach those who can benefit from them the most. Additionally, Toms invests in initiatives that support education, healthcare, and economic empowerment in these communities.

Embracing Sustainability

In addition to their social initiatives, Toms also prioritizes sustainability in their manufacturing process. The company strives to minimize its environmental impact by implementing eco-friendly practices throughout the production cycle. This includes reducing waste, recycling materials, and using renewable energy sources whenever possible.

Toms also embraces sustainable packaging solutions to minimize their carbon footprint. They use recycled materials for their shoeboxes and incorporate eco-friendly printing methods. These efforts reflect Toms’ commitment to not only creating stylish and comfortable shoes but also being mindful of their environmental impact.

In conclusion, Toms shoes are manufactured through a meticulous process that combines innovative design, skilled craftsmanship, and a commitment to social responsibility. From the initial design phase to the final assembly and finishing, each step is carefully executed to ensure the creation of high-quality and socially conscious footwear. By choosing Toms shoes, consumers not only embrace style and comfort but also contribute to making a positive impact on communities in need.

Key Takeaways: How Are Toms Shoes Manufactured?

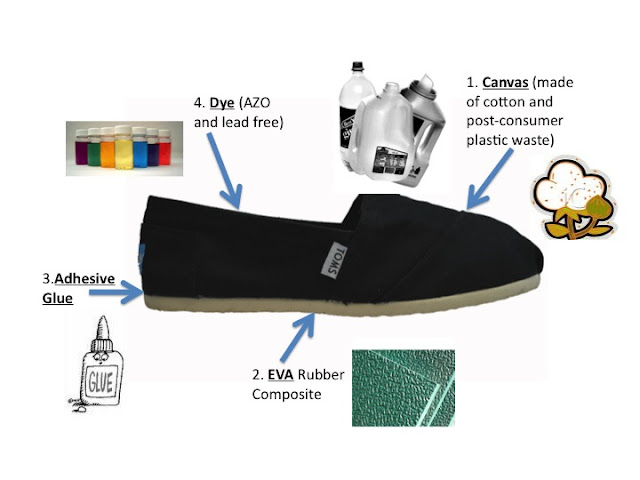

- Toms Shoes are manufactured using sustainable materials and ethical production practices.

- The manufacturing process starts with sourcing eco-friendly materials like organic cotton and recycled plastic.

- Skilled artisans assemble the shoes by hand, paying attention to quality and detail.

- Toms Shoes are known for their comfortable and lightweight design.

- For every pair of Toms Shoes purchased, a pair is donated to a child in need.

Frequently Asked Questions

How are Toms shoes manufactured?

Toms shoes are manufactured using a combination of traditional and modern techniques. The process begins with the sourcing of high-quality materials such as canvas, leather, and rubber. These materials are carefully selected to ensure durability and comfort.

Once the materials are ready, the shoes go through a series of manufacturing steps. First, the patterns for the different shoe components are cut from the chosen materials. Skilled craftsmen then stitch these components together using strong nylon thread. This stitching process ensures the shoes are sturdy and long-lasting.

What kind of materials are used in Toms shoes?

Toms shoes are known for their use of high-quality materials. The uppers of Toms shoes are typically made from canvas, which is a durable and breathable fabric. Canvas allows for flexibility and comfort while also being easy to clean.

The soles of Toms shoes are often made from rubber, which provides excellent traction and durability. Some Toms shoes also feature leather uppers, offering a more luxurious and stylish option. Overall, Toms prioritizes using sustainable and environmentally friendly materials in their manufacturing process.

Are Toms shoes handmade?

Toms shoes are not entirely handmade, but they do incorporate some handcrafted elements. While the cutting of patterns and stitching of components is done by skilled craftsmen using machines, there are certain finishing touches that require handwork.

For example, the final assembly of the shoes, including attaching the soles, may involve manual labor. Additionally, details such as hand-painted designs or embroidery on certain Toms shoe styles are done by hand. This combination of handcrafted and machine-made processes ensures the quality and uniqueness of each pair of Toms shoes.

Where are Toms shoes manufactured?

Toms shoes are manufactured in various countries around the world. The company has production facilities in China, Ethiopia, and other locations. Toms has established partnerships with manufacturers in these countries to ensure ethical and responsible production practices.

By manufacturing shoes in different regions, Toms is able to support local economies and provide job opportunities in communities where they operate. The company also maintains strict quality control measures to ensure that all shoes meet their high standards regardless of where they are produced.

What steps does Toms take to ensure ethical manufacturing?

Ethical manufacturing is a core value for Toms. The company has implemented several measures to ensure that their shoes are produced in a responsible and ethical manner. Toms works closely with their manufacturing partners to ensure fair labor practices and safe working conditions.

They also require their partners to adhere to strict environmental standards, minimizing the impact of production on the environment. Toms regularly audits their manufacturing facilities to ensure compliance with these standards. In addition, Toms is committed to giving back to communities in need through their One for One program, which provides shoes to children in need for every pair of Toms shoes purchased.

Toms Manufacturing Plant Tour

Final Thoughts

And there you have it, folks! The fascinating journey of Toms shoes, from the initial concept to the final product, is truly remarkable. Throughout this article, we’ve delved into the intricate details of how Toms shoes are manufactured, and it’s clear that every step of the process is carefully executed to ensure the highest quality and ethical standards.

From sourcing sustainable materials to implementing fair labor practices, Toms is committed to making a positive impact on both the environment and the lives of those involved in the production. Their dedication to social responsibility sets them apart in the fashion industry and has earned them a loyal customer base.

So, the next time you slip on a pair of Toms shoes, you can feel good knowing that you’re not only wearing a stylish and comfortable pair of shoes but also supporting a company that is making a difference in the world. Keep rocking those Toms and walking with purpose!