If you’re a fan of Brooks shoes, you may have wondered how these high-performance running shoes are made. From the materials used to the intricate construction process, every aspect of Brooks shoes is carefully crafted to provide the best possible experience for runners. In this article, we’ll take a closer look at how Brooks shoes are made, so you can appreciate the level of detail and precision that goes into each pair.

How Are Brooks Shoes Made?

Brooks shoes are made with precision and care to provide the best possible experience for athletes and runners. The company uses high-quality materials and advanced manufacturing techniques to ensure that every shoe is comfortable, durable, and supportive. Here’s a detailed look at how Brooks shoes are made:

Design and Development

The design and development process for Brooks shoes is a combination of art and science. The company’s team of designers and engineers work together to create shoes that are not only visually appealing but also functional and comfortable.

The design process begins with a concept, which is then refined through sketches and computer-generated models. Once the design is finalized, a prototype is created and tested to ensure that it meets Brooks’ standards for performance and quality.

Brooks shoes are designed with the needs of runners and athletes in mind. The company uses data from biomechanical research to create shoes that support the foot and enhance performance.

Materials

Brooks shoes are made with high-quality materials that are durable and comfortable. The company uses a variety of materials depending on the shoe’s purpose and design.

The upper part of the shoe is typically made with a combination of synthetic materials and mesh. This allows for breathability and flexibility while also providing support and structure. The midsole is made with foam, which provides cushioning and shock absorption.

The outsole is made with rubber, which provides traction and durability. Brooks uses different types of rubber depending on the shoe’s intended use. For example, shoes designed for trail running may have a more rugged outsole than shoes designed for road running.

Manufacturing

Brooks shoes are manufactured using advanced techniques to ensure consistency and quality. The company’s manufacturing facilities are located in Vietnam and China.

The manufacturing process begins with cutting the materials to the correct size and shape. The upper is then stitched together and attached to the midsole. The outsole is attached last, and the shoe is inspected for quality before being boxed and shipped.

Brooks shoes are made using a combination of hand and machine work. This allows for a high level of precision and attention to detail.

Benefits of Brooks Shoes

Brooks shoes are designed with the needs of runners and athletes in mind. They provide support, cushioning, and durability, which is essential for high-performance activities.

One of the main benefits of Brooks shoes is their comfort. The company uses high-quality materials and advanced manufacturing techniques to ensure that every shoe is comfortable and supportive.

Brooks shoes also provide excellent traction, which is important for runners and athletes who need to maintain their balance and stability. The shoes are designed to grip the ground and provide a stable base for the foot.

Brooks vs. Other Brands

Brooks shoes are known for their quality and performance. They are designed with the needs of runners and athletes in mind and are made with high-quality materials.

Compared to other brands, Brooks shoes are often more durable and long-lasting. They are also known for their comfort and support, which is essential for high-performance activities.

Overall, Brooks shoes are a great choice for runners and athletes who want high-quality, comfortable, and supportive footwear. With their advanced design, materials, and manufacturing techniques, Brooks shoes are sure to meet the needs of even the most demanding users.

Frequently Asked Questions

Brooks shoes are known for their quality, durability, and comfort. If you’re curious about how these shoes are made, check out these frequently asked questions:

What materials are used to make Brooks shoes?

Brooks uses a variety of materials to make their shoes, including synthetic fabrics, leather, rubber, and foam. Each material is carefully selected to ensure the shoe is durable, comfortable, and supportive. The materials are often sourced from multiple countries to ensure the highest quality.

The shoes are also designed to be environmentally friendly, with many of the materials being recycled or sustainable. Brooks is committed to reducing their carbon footprint and creating shoes that are both comfortable and eco-friendly.

How are Brooks shoes designed?

The design process for Brooks shoes is extensive and involves input from athletes, designers, and biomechanics experts. They use 3D printing technology to create prototypes and test the shoes on real runners to ensure they are comfortable and supportive.

The shoes are designed with specific types of running in mind, such as trail running or long-distance running. Each shoe is created to meet the unique needs of the runner, providing the right amount of cushioning, support, and stability.

Where are Brooks shoes manufactured?

Brooks shoes are manufactured in multiple countries, including China, Vietnam, and Indonesia. The company has strict manufacturing standards to ensure the shoes are made with high-quality materials and ethical practices.

Brooks works closely with their manufacturing partners to ensure fair labor practices and safe working conditions. They also have a code of conduct that all partners must follow to ensure the shoes are made in an ethical and responsible manner.

How are Brooks shoes tested?

Before Brooks shoes are released to the public, they go through extensive testing to ensure they meet the company’s high standards. The shoes are tested by real runners in various conditions, such as on different types of terrain and in different weather conditions.

The shoes are also tested in a lab using biomechanical testing equipment to measure the shoe’s performance, support, and stability. This testing ensures that the shoes meet the needs of runners and provide the comfort and support they need to perform their best.

What makes Brooks shoes different from other running shoes?

Brooks shoes are designed with the runner in mind, providing the right amount of support, cushioning, and stability for each type of running. The company has a team of experts who work to create shoes that meet the unique needs of runners, whether they are running on a trail or a road.

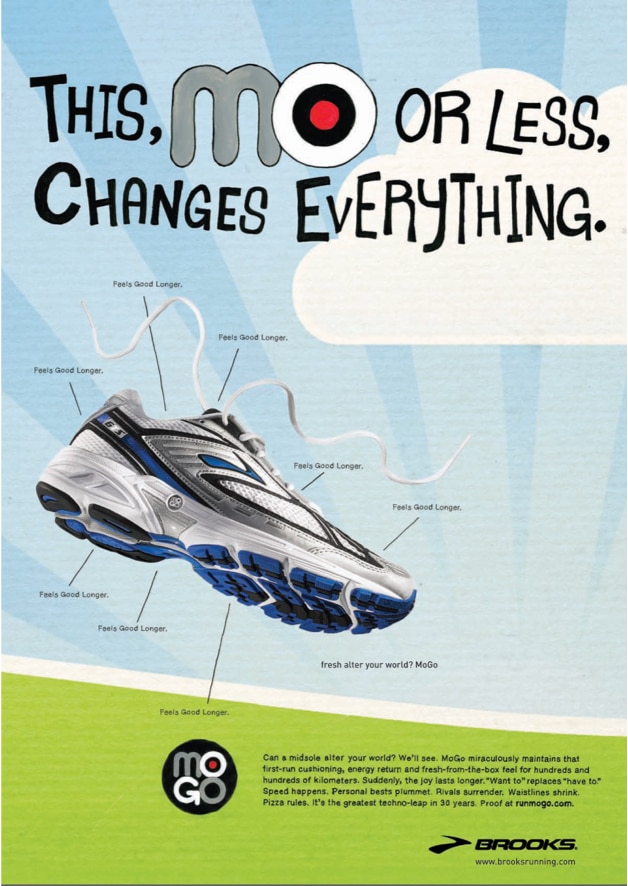

Brooks shoes also use innovative technology, such as DNA Loft and BioMoGo DNA, to provide cushioning and support without adding extra weight to the shoe. This allows runners to perform at their best without being weighed down by heavy shoes.

How they make Running Shoes | in the Brooks factory in China

In conclusion, the process of making Brooks shoes is an intricate and fascinating one. From the design phase to the final product, every step is taken with the utmost care and attention to detail. The use of high-quality materials and advanced technologies ensures that these shoes are not only stylish but also durable and comfortable.

Furthermore, the company’s commitment to sustainability and ethical practices is commendable. By using recycled materials and minimizing waste, Brooks is doing its part to protect the environment. And by treating its employees and suppliers with respect and fairness, it is creating a positive impact on society as a whole.

Overall, wearing a pair of Brooks shoes is not just about fashion or function, but also about supporting a brand that values quality, sustainability, and social responsibility. So if you’re looking for a pair of shoes that not only look and feel great but also align with your values, consider giving Brooks a try.